Introduction

Coating inspection is a critical process that ensures the quality and longevity of coatings in various industries. It involves assessing coatings for adherence, thickness, and other essential attributes. Utilizing specialized coating inspection tools is paramount in achieving accurate and reliable results.

Definition and Importance of Coating Inspection in Various Industries

Coating inspection is a crucial process employed in diverse industries to ensure the quality, durability, and effectiveness of protective coatings applied to surfaces. This process involves assessing the coating’s adherence, thickness, uniformity, and other properties to guarantee that it meets the desired standards. Coatings play a vital role in protecting structures, equipment, and products from corrosion, wear and tear, weathering, and chemical exposure. A thorough inspection helps maintain the coating’s integrity, prolong the lifespan of the coated item, and enhance overall operational efficiency and safety.

Significance of Using Specialized Tools for Coating Inspection

Utilizing specialized coating inspection tools is fundamental to achieving accurate and reliable results during the inspection process. These tools are designed to measure coating thickness, detect flaws, assess adhesion, and analyze other critical parameters that determine the coating’s quality and performance. The precision and efficiency offered by specialized coating inspection tools significantly contribute to meeting industry standards and ensuring optimal protection for the underlying surfaces. These tools empower professionals to make informed decisions regarding maintenance, repairs, or re-coating, ultimately enhancing the longevity and efficiency of the coated structures or products.

Types of Coating Inspection Tools

Coating Inspection Tools play a critical role in ensuring the quality and durability of coated surfaces in various industries. These tools help in assessing and measuring parameters such as surface preparation, film thickness, adhesion, holiday detection, and gloss. In this comprehensive guide, we will delve into various types of coating inspection tools, how they enhance the quality and performance of coatings, and their specific applications.

Surface Preparation Tools

- Abrasive Blast Equipment: Abrasive blast equipment is fundamental in surface preparation for coatings. It involves propelling abrasive particles onto the surface to remove contaminants, rust, or old coatings, ensuring a clean and profiled surface for proper adhesion.

- Surface Profile Gauges: Surface profile gauges measure the profile or roughness of a prepared surface. This measurement is crucial, as coatings adhere better to surfaces with an appropriate profile.

- Surface Cleanliness Testers: Surface cleanliness testers help verify that the surface is free from contaminants like oil, grease, or residues that can affect coating adhesion and performance.

Wet Film Thickness (WFT) Measurement Tools

- Wet Film Thickness Gauges: Wet film thickness gauges measure the thickness of a coating while it is still wet, ensuring that the coating is applied as per specifications and will achieve the desired dry film thickness.

- Comb Gauges: Comb gauges are comb-like tools used to measure the wet film thickness during the coating application, ensuring consistent and accurate application.

- Micrometers: Micrometers are precise instruments used for measuring the wet film thickness at various points on a coated surface, providing a detailed assessment of application consistency.

Dry Film Thickness (DFT) Measurement Tools

- Magnetic Induction Gauges: Magnetic induction gauges measure the dry film thickness of coatings using magnetic fields, providing non-destructive and accurate measurements.

- Eddy Current Gauges: Eddy current gauges use electromagnetic induction to measure the dry film thickness, suitable for non-metallic coatings on conductive substrates.

- Ultrasonic Gauges: Ultrasonic gauges use sound waves to measure the thickness of coatings, providing precise and versatile measurements for a wide range of coatings.

Adhesion Testing Tools

- Pull-off Adhesion Testers: Pull-off adhesion testers determine the adhesion strength of a coating by applying a controlled force and measuring the pull-off strength.

- Cross-cut Adhesion Testers: Cross-cut adhesion testers evaluate adhesion by creating a grid of cuts in the coating and assessing the extent of adhesion loss.

- Tape Adhesion Testers: Tape adhesion testers determine the adhesion of coatings by applying and removing tape from the coated surface, evaluating the level of coating adhesion.

Selection and Proper Use of Coating Inspection Tools

Coating inspection tools are crucial for ensuring the quality and performance of coatings applied in various industries. The correct selection and proper use of these tools are paramount to achieve the desired coating quality and, ultimately, the longevity and efficiency of the coated surface.

Factors influencing tool selection

When selecting coating inspection tools, several factors need to be taken into account to ensure their appropriateness for the specific coating application:

- Coating Type and Characteristics: Different coatings require different inspection tools. For instance, the tools suitable for inspecting a thick protective coating may differ from those used for a thin decorative coating.

- Surface Material: The material of the surface being coated affects tool selection. Tools must be compatible with the surface material to provide accurate measurements and assessments.

- Coating Thickness: Some tools are specialized for measuring coating thickness accurately. The expected coating thickness will influence the choice of the appropriate tool.

- Environmental Conditions: Tools should be selected considering the environmental conditions of the application site, such as temperature, humidity, and exposure to chemicals or corrosive elements.

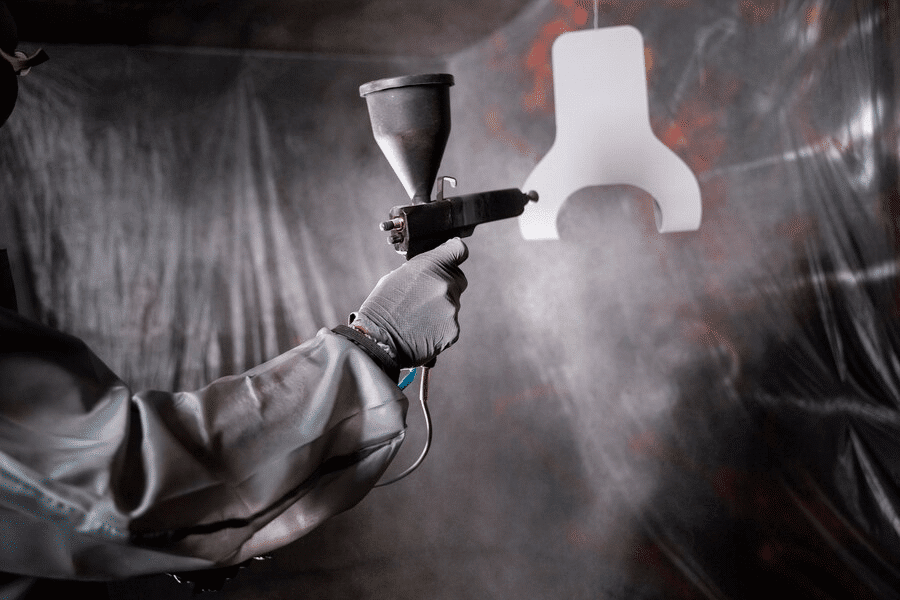

- Application Method: Depending on whether the coating is applied using a brush, spray, or another method, the tool’s specifications may vary to best evaluate the coating’s uniformity.

Calibration and maintenance of inspection tools

Proper calibration and regular maintenance of coating inspection tools are vital to ensure their accuracy and reliability:

- Calibration: Coating inspection tools should be calibrated regularly as per the manufacturer’s guidelines or industry standards to maintain accurate measurements.

- Verification Checks: Perform routine verification checks to ensure that the tools are providing precise measurements. Any discrepancies should be addressed promptly.

- Maintenance: Follow the maintenance schedule provided by the manufacturer to keep the tools in optimal condition. This may include cleaning, adjusting, and replacing parts as needed.

- Record-Keeping: Maintain a record of calibration dates, verification checks, and maintenance activities for each tool to track their performance and compliance with standards.

Safety considerations during tool use

Ensuring the safety of personnel using coating inspection tools is of paramount importance:

- Training: Provide comprehensive training to personnel on the correct use of coating inspection tools, emphasizing safety protocols and practices.

- Protective Gear: Mandate the use of appropriate personal protective equipment (PPE), such as gloves, goggles, and masks, to safeguard against potential hazards during tool use.

- Tool Handling: Instruct users on proper handling techniques to prevent injuries or accidents while using the tools.

- Tool Storage: Establish a designated storage area for coating inspection tools to minimize the risk of damage or mishandling when not in use.

By carefully considering factors influencing tool selection, implementing proper calibration and maintenance procedures, and prioritizing safety during tool use, coating inspection tools can effectively enhance the quality and performance of coatings, contributing to a durable and reliable finished product.

Best Practices in Coating Inspection

Coating inspection is a critical process to ensure the quality and performance of coatings in various industries. Utilizing the right coating inspection tools is essential for achieving optimal results. In this section, we will explore the best practices in coating inspection, focusing on pre-inspection preparation, the step-by-step inspection process, and effective data recording and interpretation.

Pre-inspection preparation

Before commencing the actual inspection, thorough pre-inspection preparation is crucial to streamline the process and enhance efficiency. Coating inspection professionals should adhere to the following steps:

- Reviewing Specifications: Understand the specific requirements and standards for the coating being applied. This ensures that inspections align with the defined guidelines.

- Calibrating Equipment: Verify and calibrate all inspection tools to ensure accurate measurements and readings during the inspection process.

- Safety Measures: Ensure that appropriate safety measures are in place for both the inspectors and the environment where the inspection will take place.

- Identifying Inspection Points: Identify and mark the areas to be inspected. This includes assessing critical points and potential vulnerable areas in the coating.

Step-by-step inspection process

The inspection process involves a systematic approach to evaluate the coating’s quality. By following a structured procedure, inspectors can effectively assess the coating’s performance. The steps in the inspection process are as follows:

- Surface Preparation Inspection: Check the surface preparation for proper cleanliness and profile. Ensure that any contaminants or residues have been adequately removed.

- Coating Application Inspection: Evaluate the coating application technique to ensure even and consistent coverage. Verify that the specified coating thickness is achieved and within acceptable tolerances.

- Adhesion Inspection: Conduct adhesion tests to ensure the coating adheres securely to the substrate. Assess the adhesion quality to prevent potential coating failures.

- Visual Inspection: Perform a thorough visual inspection to identify any visible defects, such as pinholes, blisters, cracks, or uneven coating.

Data recording and interpretation

Accurate and detailed data recording during the inspection is vital for documentation, analysis, and future reference. The steps for effective data recording and interpretation are as follows:

- Record Keeping: Document all inspection findings, measurements, and observations using appropriate forms or digital tools. Include details such as inspection date, location, inspection points, and results of each inspection step.

- Photographic Evidence: Capture clear photographs of the coated surfaces, highlighting any defects or areas of concern for a comprehensive visual record.

- Data Analysis: Analyze the collected data to identify trends, potential issues, or areas for improvement in the coating application process.

Use the inspection data to make informed decisions regarding maintenance, repairs, or future coating projects.

Case Studies and Applications

Coating inspection tools play a pivotal role in ensuring the quality and performance of coatings across various industries. In this section, we will delve into real-world applications and success stories that underscore the significance of effective coating inspection tools.

Real-world applications of coating inspection tools

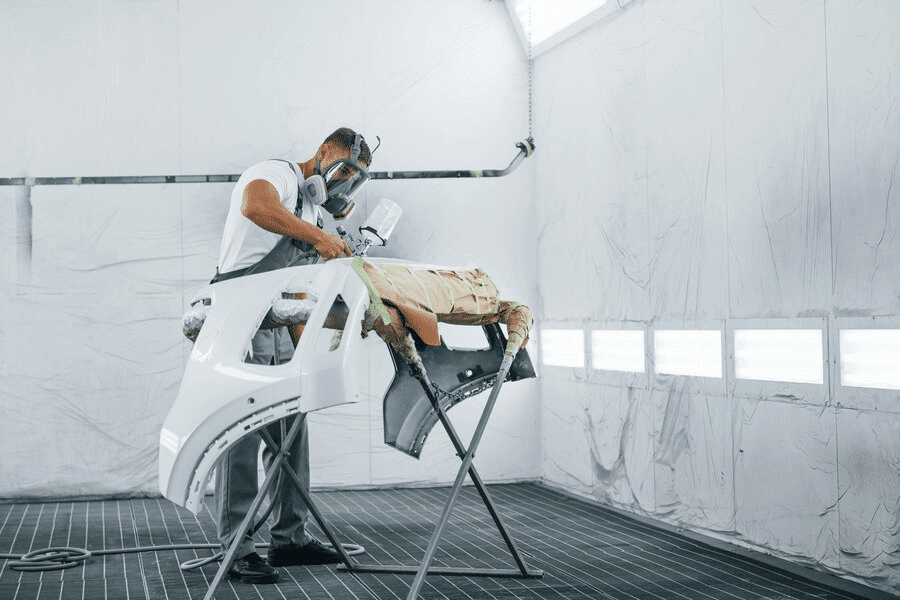

- Automotive Industry: In the automotive industry, coating inspection tools are indispensable for ensuring the quality and durability of the paint and protective coatings on vehicles. Tools such as thickness gauges and adhesion testers are used to measure coating thickness and adhesion strength, ensuring compliance with industry standards and enhancing the longevity of the coating.

- Aerospace Sector: Coating inspection is crucial in the aerospace sector to guarantee the safety and performance of aircraft components. Coating thickness gauges are utilized to monitor the thickness of anti-corrosion coatings on critical parts, ensuring they meet stringent aviation regulations and standards.

- Marine and Offshore Applications: In the marine and offshore industries, coating inspection tools are vital for assessing the integrity of protective coatings on ships, oil rigs, and other marine structures. These tools aid in detecting coating defects such as cracks, blisters, or disbondments, enabling timely maintenance and enhancing the longevity of the coatings.

Success stories showcasing the impact of effective coating inspection

- Increased Efficiency and Cost Savings: A leading automotive manufacturer implemented advanced coating inspection tools in their production process. By accurately measuring coating thickness and quality, they optimized the application process, reducing excess coating usage. This led to significant cost savings and improved operational efficiency.

- Enhanced Product Performance: In the aerospace industry, a company adopted state-of-the-art coating inspection tools to ensure the precise application of coatings on aircraft components. This meticulous monitoring resulted in coatings that met required specifications, contributing to enhanced performance, fuel efficiency, and overall safety of the aircraft.

- Longevity and Durability: A marine engineering company integrated coating inspection tools into their maintenance routine for offshore platforms. Regular inspections using these tools identified early signs of coating degradation, enabling proactive maintenance. As a result, the protective coatings exhibited increased longevity, reducing maintenance costs and ensuring a safer offshore environment.

Conclusion

In conclusion, effective inspection of coatings is paramount in maintaining the longevity and performance of various structures and equipment. Utilizing advanced coating inspection tools is crucial for ensuring the quality and durability of coatings, identifying potential issues, and facilitating timely maintenance. For individuals seeking to enhance their knowledge and proficiency in coating inspection.

The CORCON Institute of Corrosion offers comprehensive courses designed to equip professionals with the necessary skills and expertise. These courses provide valuable insights into the latest techniques, tools, and best practices in coating inspection, empowering individuals to contribute to the integrity and reliability of coatings across industries. Investing in education through the CORCON Institute of Corrosion can significantly contribute to a successful and fulfilling career in the field of coating inspection.

Image Reference: Freepik

Disclaimer: All trademarks, logos, and brand names are the property of their respective owners. All company, product, and service names used in this website are for identification purposes only. Use of these names, trademarks, and brands does not imply endorsement.