Introduction

Coating inspectors play a critical role in ensuring the quality and durability of protective coatings applied to various surfaces in a wide range of industries. These professionals are responsible for meticulously examining and evaluating coatings applied to structures, equipment, pipelines, and other surfaces to ensure compliance with industry standards, specifications, and safety regulations. Their role is vital in maintaining the integrity of the coated surface, preventing corrosion, enhancing longevity, and ensuring the safety of both personnel and the environment.

Role of Coating Inspectors in Various Industries

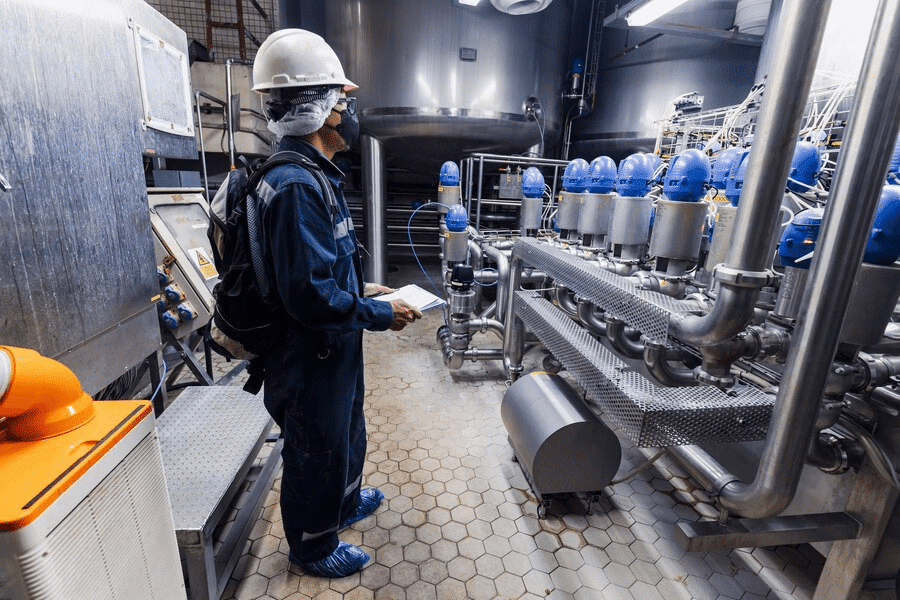

Oil and Gas Industry

Coating inspectors in the oil and gas industry are tasked with examining protective coatings on pipelines, storage tanks, and offshore platforms. These coatings are essential in preventing corrosion and maintaining the structural integrity of critical components.

Construction and Infrastructure

Coating inspectors in construction and infrastructure assess protective coatings on bridges, buildings, highways, and other structures. Properly coated structures resist deterioration due to environmental factors, such as moisture, chemicals, and UV radiation, ensuring longevity and safety.

Marine Industry

In the marine industry, coating inspectors evaluate coatings on ships, docks, and maritime structures. These coatings protect vessels from the corrosive effects of saltwater and provide a barrier against marine organisms, maintaining the ship’s performance and lifespan.

Aerospace Industry

Coating inspectors in the aerospace sector monitor coatings on aircraft, spacecraft, and related components. The coatings ensure resistance to extreme temperatures, pressure changes, and atmospheric conditions, contributing to the safety and efficiency of aerospace vehicles.

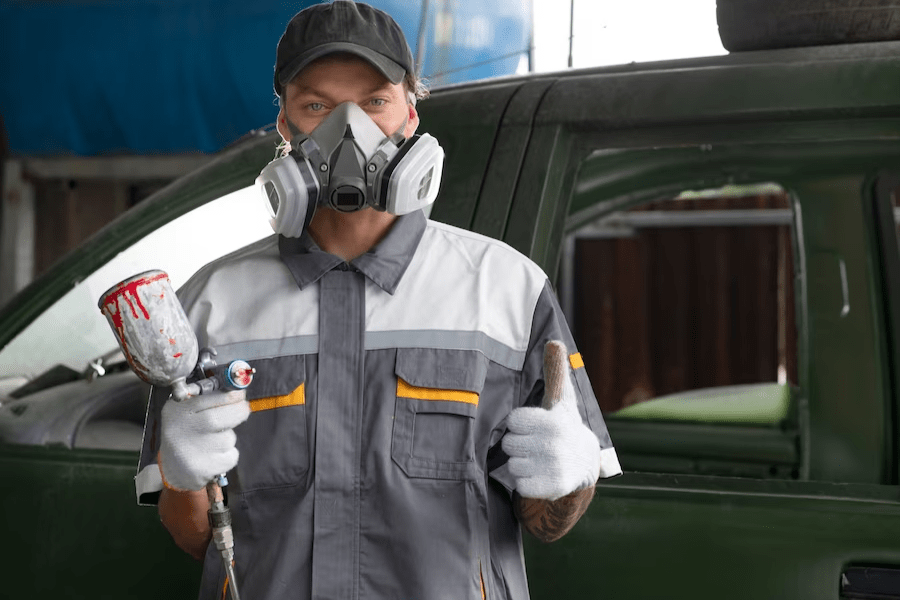

Automotive and Transportation:

Coating inspectors in this industry focus on coatings applied to automobiles, trains, and other transportation vehicles. Properly coated vehicles are protected from rust, abrasion, and harsh weather conditions, enhancing their appearance and durability.

Importance of Coating Inspections for Quality Assurance:

Durability and Longevity

Coating inspections verify that the protective coatings adhere effectively to the surface, ensuring the longevity of the structure or equipment by guarding against corrosion and other forms of degradation.

Quality Control

Through meticulous inspections, coating inspectors ascertain that the coatings meet specified industry standards and requirements. This quality control is crucial in maintaining the desired level of protection and safety.

Cost-Efficiency

Coating inspections help identify any issues early in the coating application process, allowing for timely corrections. This prevents costly rework, reduces material wastage, and ultimately saves resources.

Safety and Environmental Compliance

Properly applied coatings, verified through inspections, ensure the safety of workers, the public, and the environment by containing hazardous materials and preventing leaks or spills.

Client Satisfaction

Adhering to high-quality coating standards and conducting thorough inspections ensures client satisfaction by delivering a product or structure that meets or exceeds expectations in terms of appearance, durability, and safety.

Key Responsibilities of a Coating Inspector

A coating inspector plays a crucial role in ensuring the quality and durability of coatings applied to various surfaces, such as structures, equipment, or pipelines. Their primary responsibilities encompass meticulous inspections throughout the coating application process. The importance of their role cannot be overstated, as inadequate or faulty coatings can lead to significant consequences, including structural degradation, safety hazards, and financial losses.

Key Responsibilities of a Coating Inspector:

Pre-Inspection Preparation:

Reviewing project specifications, standards, and requirements to understand the scope of work.

Familiarize oneself with the coating materials, application methods, and safety protocols.

Verification of Surface Preparation:

Ensuring that the surface to be coated is adequately prepared by checking for cleanliness, profile, and any defects that might affect adhesion.

Material and Equipment Inspection:

Verifying the quality and suitability of coating materials, including paint, primers, and solvents.

Inspecting and calibrating equipment such as spray guns, pumps, and mixing machines to ensure proper application.

Application Monitoring:

Overseeing the coating application process to confirm adherence to specified procedures and standards.

Checking for proper thickness, coverage, and consistency of the applied coating.

Adherence to Health and Safety Guidelines:

Ensuring that all safety protocols and regulations are followed during the coating process to protect both workers and the environment.

Documentation and Reporting:

Maintaining accurate records of inspection results, including photographs and reports.

Providing detailed reports to project stakeholders, highlighting any deviations from specifications and suggesting corrective actions.

Problem Identification and Troubleshooting:

Identifying any defects, irregularities, or issues during or after the application, and recommending appropriate corrective measures.

Collaborating with project teams to address and rectify any coating-related problems.

Compliance with Standards and Codes:

Confirm that the coating application adheres to industry standards, codes, and specifications relevant to the project.

Importance of Meticulous Inspections

Durability and Longevity:

Meticulous inspections ensure that coatings are applied correctly, enhancing the durability and longevity of the structure or equipment being coated.

Corrosion Prevention:

Properly applied coatings protect against corrosion, a significant concern in sectors like oil and gas, maritime, and infrastructure.

Environmental Impact:

Correct application and inspection reduce the risk of environmental contamination caused by improper handling or disposal of coating materials.

Operational Efficiency:

Adequately coated equipment and surfaces experience fewer operational disruptions, contributing to overall efficiency and cost-effectiveness.

Public Safety and Health:

Inspections ensure that coatings meet safety standards, preventing potential hazards to the public and workers.

Qualifications and Educational Requirements

Discussing the educational background and qualifications necessary to become a coating inspector.

Highlighting the relevant courses and certifications that are beneficial for aspiring coating inspectors.

Becoming a coating inspector involves a combination of educational qualifications, relevant courses, and certifications to ensure a comprehensive understanding of coating materials, application processes, safety standards, and quality control measures. Below is a detailed breakdown of the qualifications and educational requirements for aspiring coating inspectors:

Educational Background:

High School Diploma or Equivalent: Begin with a strong educational foundation by completing a high school diploma or its equivalent. Courses in mathematics, chemistry, physics, and technical drawing can be particularly beneficial.

Associate’s or Bachelor’s Degree: While not always mandatory, obtaining an associate’s or bachelor’s degree in a relevant field such as materials science, engineering, chemistry, or a related discipline provides a sol id academic foundation.

Relevant Courses:

Materials Science: Understanding the properties and behavior of various materials used in coatings is fundamental. Courses covering topics like material properties, corrosion, and surface preparation are crucial.

Surface Preparation Techniques: Learn about different surface preparation methods, including abrasive blasting, chemical cleaning, and mechanical surface preparation.

Coating Application Methods: Gain knowledge about the various techniques for applying coatings, such as spray application, brush and roller application, and immersion coating.

Inspection Techniques: Courses focusing on inspection methodologies, defect detection, and quality assessment are vital for aspiring coating inspectors.

Health and Safety Standards: Understand occupational health and safety standards relevant to coating applications to ensure a safe work environment for all involved.

Additional Skills and Qualities:

Attention to Detail: Coating inspectors need to be meticulous in their work to detect even minor defects in coatings.

Communication Skills: Effective communication with clients, contractors, and team members is crucial to convey inspection findings and ensure project success.

Problem-Solving Skills: Coating inspectors should have the ability to troubleshoot issues and recommend appropriate solutions during the coating process.

Familiarity with Industry Standards: Staying updated with the latest industry standards and best practices is essential for a successful coating inspector.

Experience and On-the-Job Training: While not a formal requirement, gaining practical experience through internships, apprenticeships, or on-the-job training can significantly enhance one’s skills and employability as a coating inspector.

Challenges and Opportunities in the Coating Inspection Field

Challenges in the Coating Inspection Field:

Diverse Coating Types and Applications:

Challenge: Coatings vary based on the substrate, industry, and purpose, making it challenging for inspectors to be proficient in all types.

Solution: Ongoing training and certification programs that focus on various coating types and applications can help inspectors stay updated and enhance their knowledge.

Evolving Regulations and Standards:

Challenge: Regulatory requirements and industry standards are constantly evolving, requiring inspectors to stay updated and comply with the latest guidelines.

Solution: Regular participation in workshops, seminars, and industry conferences to stay informed about regulatory changes and networking with industry peers can help in understanding and implementing the latest standards.

Technological Advancements:

Challenge: Rapid advancements in inspection technologies, such as non-destructive testing methods and digital tools, may overwhelm inspectors who are not well-versed in these technologies.

Solution: Continuous education and training in the latest inspection technologies and tools, along with hands-on experience, are crucial for staying relevant and competitive in the field.

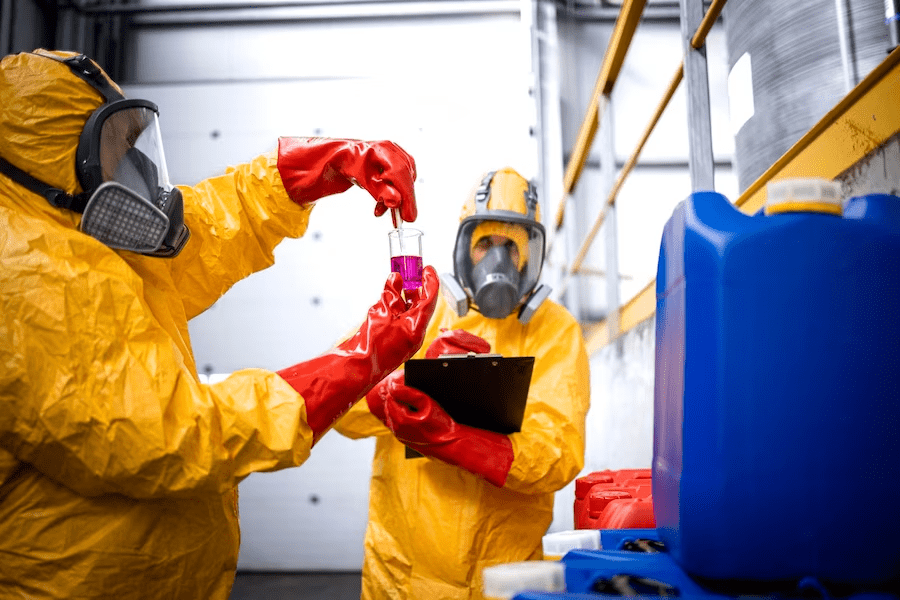

Environmental and Safety Concerns:

Challenge: Adhering to environmental and safety protocols while performing inspections can be challenging, particularly in hazardous or sensitive areas.

Solution: Enhanced safety training, access to appropriate safety equipment, and strict adherence to safety guidelines are essential to mitigate risks and ensure a safe working environment.

Quality Assurance and Client Expectations:

Challenge: Meeting client expectations for high-quality coatings while adhering to project timelines and budget constraints is a balancing act.

Solution: Effective communication with clients to manage expectations, clear documentation of inspection results, and proactive problem-solving can help achieve a balance between quality and project constraints.

Opportunities for Career Growth and Specialization:

Advanced Certifications and Specialization:

Coating inspectors can pursue advanced certifications in specific coating types (e.g., corrosion-resistant coatings, intumescent coatings) or techniques (e.g., thermal imaging, ultrasonic testing) to specialize and enhance their expertise.

Project Management and Leadership Roles:

Experienced inspectors can transition into project management or leadership roles, overseeing teams of inspectors and managing complex coating projects.

Research and Development:

Opportunities exist in research and development roles, contributing to the innovation of new coating materials, technologies, and inspection methods.

Consulting and Training:

Coating inspectors with substantial experience and knowledge can become consultants or trainers, providing guidance, training, and consulting services to other professionals and organizations in the field.

Entrepreneurship:

Establishing an inspection consulting firm or a business focused on providing specialized coating inspection services can be a viable career option for experienced coating inspectors.

Conclusion

In conclusion, the role of a coating inspector in India holds immense significance in maintaining the integrity and durability of various structures and equipment across diverse industries. The demand for skilled coating inspectors is steadily increasing, offering a multitude of opportunities for those aspiring to enter this field. Prospective coating inspectors should focus on acquiring the requisite qualifications, certifications, and skills to excel in their careers.

Moreover, institutes like CORCON Institute of Corrosion play a pivotal role in providing specialized courses to individuals looking to establish a career in corrosion and coating inspection. The courses offered by CORCON Institute of Corrosion equip students with the knowledge and expertise required to succeed in the competitive world of coating inspection. Investing in education and training through reputable institutions like CORCON Institute of Corrosion is a stepping stone towards a fulfilling and prosperous career as a coating inspector.

Image Reference: Freepik

Disclaimer: All trademarks, logos, and brand names are the property of their respective owners. All company, product, and service names used in this website are for identification purposes only. Use of these names, trademarks, and brands does not imply endorsement.