Introduction

Becoming a coating inspector is a career choice that demands attention to detail, technical knowledge, and a passion for ensuring the durability and safety of coated surfaces. Coating inspectors play a vital role in industries such as construction, manufacturing, and oil and gas, where protecting materials from corrosion and other forms of degradation is essential. In this guide, we will walk you through the steps and qualifications required to become a coating inspector and highlight the importance of this profession.

Understanding the Role of a Coating Inspector

What Does a Coating Inspector Do?

A coating inspector plays a crucial role in ensuring that coatings applied to various surfaces meet the required standards and specifications. Coatings are essential for protecting surfaces from corrosion, wear and tear, and other environmental factors. The coating inspector’s job is to monitor and evaluate the entire coating process to ensure the coatings are applied correctly and effectively.

Key Responsibilities of a Coating Inspector

Reviewing coating specifications

The first and fundamental responsibility of a coating inspector is to thoroughly review and understand the coating specifications provided for a particular project. These specifications outline the requirements for the type of coating to be used, application procedures, quality standards, and any other specific instructions. It’s essential for the inspector to have a clear understanding of these specifications to ensure compliance throughout the coating process.

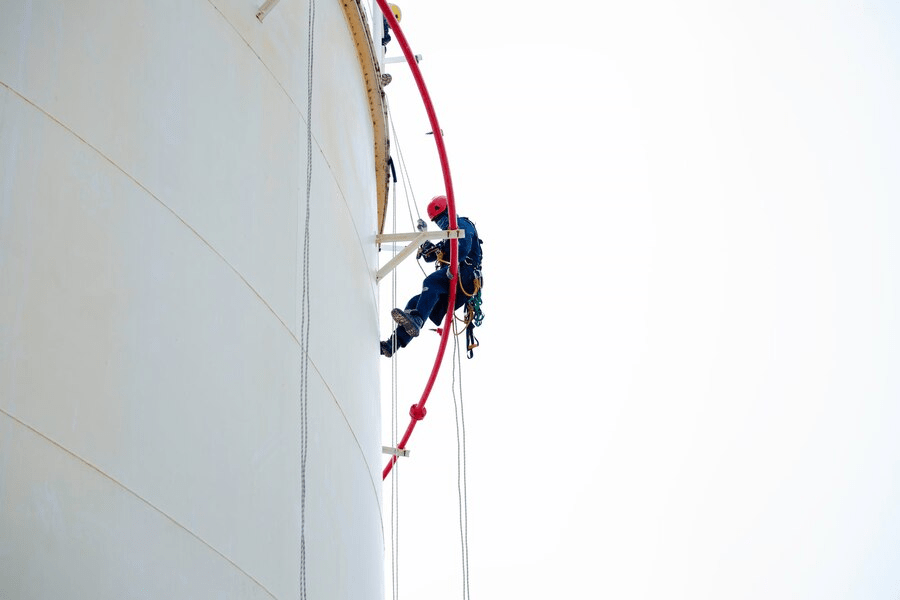

Conducting surface preparation inspections

Before applying coatings, surfaces need to be prepared properly to ensure adhesion and longevity of the coating. Coating inspectors inspect the surface preparation activities, which may include cleaning, blasting, or other methods, to ensure that the surface is free from contaminants, rust, old coatings, or any other substances that could interfere with the bonding of the new coating.

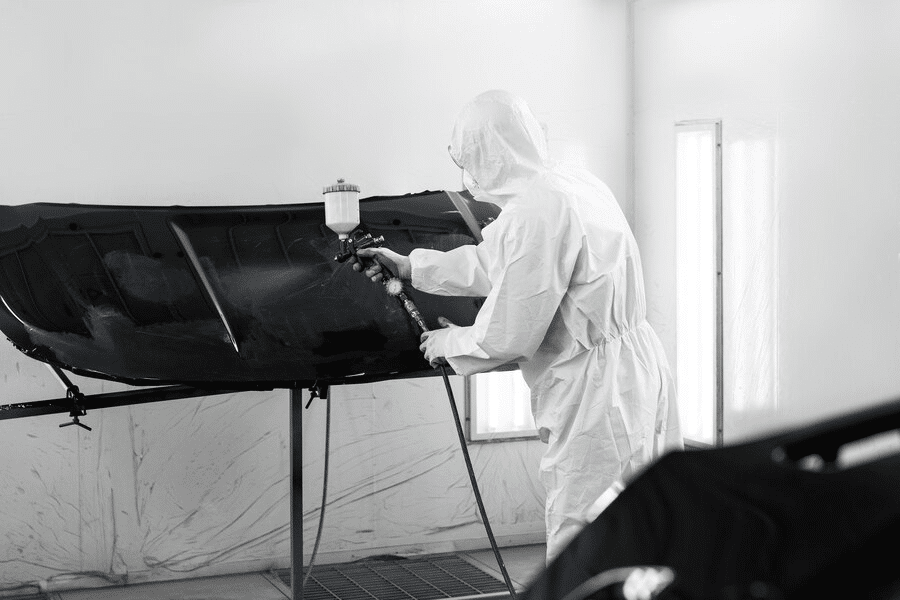

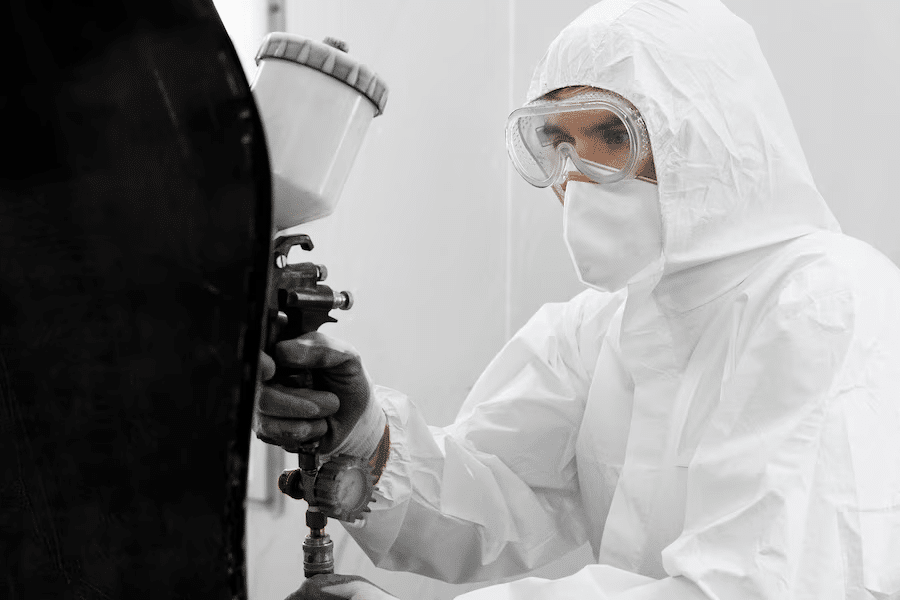

Monitoring coating application procedures

Coating application is a critical stage of the process. Coating inspectors closely monitor the application procedures to ensure they align with the specified guidelines and standards. This includes checking the equipment used, application techniques, mixing ratios of coatings, temperature, humidity, and other relevant parameters that can affect the quality of the applied coating.

Performing coating thickness measurements

Coating thickness is a vital factor in determining the performance and durability of the coating. Coating inspectors use specialized tools and devices to measure and verify the thickness of the applied coating. These measurements are compared against the specified coating thickness requirements to ensure that the coating adheres to the prescribed standards.

Identifying and addressing coating defects

Coating defects can arise during application or due to various factors such as surface conditions, application errors, or equipment malfunctions. Coating inspectors are responsible for identifying these defects, which could include blistering, peeling, pinholes, or uneven application. Once identified, inspectors work with the application team to address these issues, ensuring that the defects are corrected to meet the required quality standards.

Essential Skills and Qualities for Coating Inspectors

Technical Knowledge and Understanding

Coating inspectors must possess a strong foundation in technical knowledge related to coatings. This includes understanding various coating materials, their properties, and how they interact with different surfaces. They should be well-versed in different application techniques, industry standards, and protocols for surface preparation. Additionally, a thorough comprehension of corrosion mechanisms and effective mitigation strategies is crucial for identifying potential coating issues and ensuring the durability and performance of coatings.

Attention to Detail

Attention to detail is a fundamental quality for a coating inspector. Coatings play a critical role in protecting surfaces from corrosion, weathering, and wear. Identifying even minor defects, irregularities, or imperfections in the coating application is essential. These seemingly small issues, if overlooked, can escalate over time, leading to significant problems such as corrosion, reduced longevity of the coating, or compromised structural integrity. A meticulous eye for detail ensures that coatings meet quality standards and perform effectively over time.

Effective Communication

Coating inspectors must possess excellent communication skills to convey their findings accurately and clearly. Effective communication is vital in conveying inspection results, detailing any defects or issues found, and explaining the recommended actions or solutions. This information needs to be shared with project teams, clients, engineers, and other stakeholders involved in the project. Clarity in communication helps in achieving project goals, maintaining compliance with specifications, and fostering collaboration among team members. Clear communication also ensures that corrective measures can be taken promptly to address any identified coating concerns.

Educational and Professional Requirements

Educational Background

A strong educational foundation is crucial to becoming a coating inspector. Typically, this involves obtaining a degree or relevant coursework in fields related to engineering, material science, or a closely related discipline. These educational programs provide fundamental theoretical knowledge that forms the basis for understanding coatings, corrosion prevention, and related principles. Courses may cover topics such as material properties, chemistry, corrosion mechanisms, surface preparation, and coating application techniques.

Industry Certifications

A strong educational foundation is crucial to becoming a coating inspector. Typically, this involves obtaining a degree or relevant coursework in fields related to engineering, material science, or a closely related discipline. These educational programs provide fundamental theoretical knowledge that forms the basis for understanding coatings, corrosion prevention, and related principles. Courses may cover topics such as material properties, chemistry, corrosion mechanisms, surface preparation, and coating application techniques.

Gaining Practical Experience

Entry-Level Positions

Entry-level positions, such as coating applicator, technician, or helper, serve as the starting point for gaining practical experience in the coating industry. These positions typically do not require extensive prior experience or qualifications. As a coating applicator or technician, your main responsibilities include assisting in the application of coatings on various surfaces and substrates. You may work in diverse settings, such as construction sites, manufacturing facilities, or specialized coating service companies.

On-the-job training and Mentorship

One of the key avenues for acquiring practical experience is through on-the-job training and mentorship provided by experienced professionals in the field, particularly coating inspectors and senior technicians.

Learning from Experienced Coating Inspectors

Seek out opportunities to work alongside experienced coating inspectors. These professionals have in-depth knowledge and expertise in coating inspection methodologies and best practices. By observing and assisting them, you can learn about the critical aspects of coating inspections, including surface preparation, application procedures, quality control, and compliance with industry standards.

Valuable Insights and Guidance

Engage with your mentors and ask questions to gain valuable insights into the intricacies of coating applications. They can guide you on how to identify coating defects, assess adhesion, measure coating thickness, and troubleshoot common issues. Their mentorship provides a structured learning experience and allows you to develop a solid understanding of the industry and its specific requirements.

Skill Development and Progression

The knowledge and skills acquired through on-the-job training and mentorship serve as a foundation for your professional growth within the coating industry. As you accumulate experience and demonstrate competency, you may have opportunities to take on more challenging roles, advance to higher positions, and eventually become a mentor for aspiring professionals in the field.

Advancing Your Career

Pursuing Specializations

Specializing in specific areas within the coatings industry, such as marine coatings, industrial coatings, or aerospace coatings, can significantly enhance your career prospects. Here’s a more detailed breakdown of this aspect:

Marine Coatings

Specializing in marine coatings involves understanding the unique requirements and challenges of protecting surfaces in marine environments. This could include knowledge about anti-fouling coatings to prevent marine organisms from adhering to ship hulls, corrosion-resistant coatings for metal parts exposed to saltwater, and coatings that withstand extreme weather conditions.

Industrial Coatings

Specializing in industrial coatings focuses on coatings used in various industrial settings. This could encompass knowledge about protective coatings for machinery, equipment, pipelines, and other industrial assets. Understanding the specific needs of different industries and materials is crucial for success in this specialization.

Aerospace Coatings

Specializing in aerospace coatings involves expertise in coatings designed for aircraft and spacecraft. This specialization includes knowledge of coatings that can withstand extreme temperatures, high altitudes, and the unique environmental conditions of the aerospace industry.

Specializations like these open up niche career opportunities, allowing you to work on specialized projects and become an expert in a particular domain. Employers often seek specialists for projects that require in-depth knowledge and tailored solutions.

Continuous Learning and Professional Development

Staying current with industry trends, emerging technologies, and evolving standards is vital for your professional growth. Here’s a detailed explanation of how to achieve this:

Industry Trends

Actively follow industry publications, journals, and online platforms that provide insights into the latest trends, advancements, and developments in the coatings industry. Being aware of trends helps you adapt to changing market demands and innovate in your role.

New Technologies

Attend workshops, webinars, and training sessions that introduce new technologies and advancements in coatings. Emerging technologies often bring about improvements in coating formulations, application techniques, sustainability, and efficiency.

Evolving Standards

Regulations and standards in the coatings industry evolve over time to ensure environmental sustainability, safety, and efficacy. Keep yourself updated with these changes through seminars, conferences, or online courses focused on compliance and industry standards.

Online Courses

Enroll in online courses related to coatings technology, chemistry, application methods, or specialized areas within the industry. Online platforms offer a plethora of courses that you can access from anywhere, allowing you to enhance your knowledge and skills at your own pace.

Engaging in continuous learning and professional development not only keeps you relevant in the industry but also enhances your career prospects and earning potential. Employers value professionals who are committed to ongoing growth and are well-informed about the latest advancements in their field.

Career Opportunities for Coating Inspectors

Job Prospects

Upon successful completion of a program at CORCON Institute and obtaining relevant certifications, graduates will find themselves well-positioned for a diverse range of career opportunities in various industries. These industries actively seek qualified professionals to ensure the quality and durability of coatings used in their projects.

Construction Industry: In the construction sector, professionals with expertise in coating inspection are in high demand. They play a critical role in ensuring that coatings applied to buildings, bridges, pipelines, and other structures meet the necessary standards for durability and protection against environmental elements.

Manufacturing Industry: Manufacturing companies rely on coating inspectors to ensure that products like automotive parts, machinery, appliances, and electronics have the appropriate coatings to enhance their performance, appearance, and longevity.

Aerospace Industry: Within the aerospace sector, coating inspectors are essential for validating coatings used on aircraft components. They ensure that the coatings meet the stringent requirements for safety, performance, and resistance to extreme conditions encountered during flight.

Marine Engineering: Coating inspectors are vital in the marine engineering industry to ensure that ships, offshore platforms, and other marine structures are adequately coated to resist the corrosive effects of saltwater and harsh marine environments. This enhances the durability and longevity of these structures.

Potential Roles

Responsibilities: Conduct thorough inspections of coating applications to ensure compliance with specified standards and regulations. This includes assessing coating thickness, adhesion, surface preparation, and overall quality.

Skills Required: Attention to detail, knowledge of coating materials and applications, ability to use inspection tools and equipment, and understanding of industry standards and specifications.

Quality Control Specialist

Responsibilities: Oversee and manage quality assurance processes related to coatings, ensuring that they meet the required standards and specifications. Develop and implement quality control procedures and protocols.

Skills Required: Strong analytical and problem-solving skills, understanding of quality control principles, ability to analyze data and identify trends, and excellent communication and collaboration skills.

Corrosion Engineer

Responsibilities: Apply expertise in corrosion prevention and control, designing and implementing strategies to protect materials and structures from corrosion in various projects. Conduct corrosion assessments and recommend appropriate preventive measures.

Skills Required: Knowledge of corrosion mechanisms, understanding of material science and engineering principles, ability to develop corrosion prevention strategies, and proficiency in relevant software tools.

Staying Updated with Industry Advancements

Continuous Learning

Continuous learning is crucial in the dynamic field of coatings and corrosion. This sector is constantly evolving with advancements in technologies, new materials being introduced, and innovative methodologies being developed. To stay competitive and relevant in this ever-changing industry, it’s essential to make a commitment to continuous learning.

One of the key aspects of continuous learning is staying updated with the latest developments in the field. This can be achieved by regularly reading industry publications, which provide insights into emerging technologies, research findings, and best practices. It’s also beneficial to attend seminars, webinars, and workshops related to coatings and corrosion. These events offer opportunities to learn from experts, gain new perspectives, and stay current with the latest trends.

Join Professional Associations

Become a member of reputable professional associations such as the National Association of Corrosion Engineers (NACE) and the Society for Protective Coatings (SSPC). These associations provide access to a wealth of resources, networking opportunities, and industry events that can enhance your knowledge and career growth.

Embracing a Fulfilling Career as a Coating Inspector

Job Satisfaction

Job satisfaction refers to the overall sense of contentment and fulfillment that individuals experience in their work. In the context of being a coating inspector, this role carries significant responsibilities and offers unique opportunities for job satisfaction.

Critical Role in Ensuring Longevity and Safety

As a coating inspector, your primary responsibility is to assess and maintain the quality of coatings on various structures and equipment. These coatings are not just for aesthetic purposes; they serve a critical function in preventing corrosion, which can lead to structural damage and safety hazards. Your role is pivotal in ensuring that these coatings are applied correctly and are in good condition over time.

Contributing to a Safer World

Knowing that your work directly contributes to the safety of structures and equipment can be deeply rewarding. By identifying and addressing coating issues early on, you play a crucial role in preventing accidents, failures, and potentially catastrophic incidents. This sense of responsibility can provide a strong sense of purpose in your work.

Sustainability and Environmental Impact

Coating inspectors also contribute to sustainability efforts. Properly maintained coatings reduce the need for frequent repainting and replacements, which in turn reduces resource consumption and waste. By extending the life of coated surfaces, you’re indirectly participating in creating a more sustainable world, which can be a source of pride and satisfaction.

Problem Solving and Continuous Learning

Coating inspection often involves complex problem-solving. You need to identify issues, determine their causes, and recommend appropriate solutions. This intellectual challenge can be intellectually stimulating and satisfying. Additionally, the field of coatings is constantly evolving, requiring you to engage in continuous learning to stay updated with new materials and techniques.

Positive Impact on Others

Your work not only benefits the structures and equipment you inspect but also the people who use or depend on them. Whether it’s ensuring the safety of a bridge, an oil rig, or a chemical storage tank, your efforts directly impact the well-being and safety of others, which can be a powerful source of job satisfaction.

Recognition and Career Progression

A job well done as a coating inspector often leads to recognition and opportunities for career progression. Your expertise and dedication can lead to promotions or specialized roles within the field, further enhancing your job satisfaction.

Personal Growth

Beyond the technical aspects of the job, being a coating inspector can contribute to your personal growth. It requires attention to detail, effective communication, and the ability to work independently and as part of a team. Developing these skills can be personally enriching and add to your overall job satisfaction.

Conclusion

Becoming a coating inspector is a promising career choice in the realm of corrosion prevention and control. It demands a blend of education, practical experience, and dedication to maintaining high standards of quality and safety. CORCON Institute of Corrosion offers valuable programs that can empower you with the necessary skills and knowledge to excel in this field.

By following the steps outlined in this guide, embracing the opportunities provided by CORCON Institute, and staying updated with industry advancements, you can set yourself on the path to a fulfilling and impactful career as a coating inspector. Embrace the challenges, celebrate the successes, and take pride in the vital role you play in preserving and enhancing the durability of vital structures and assets.

Becoming a coating inspector requires a combination of formal education, industry certifications, practical experience, and a dedication to honing specific skills. Coating inspectors play a crucial role in ensuring the longevity and safety of coated surfaces across various industries.

CORCON Institute of Corrosion offers reputable courses, including those focusing on coating inspection and corrosion control. Enrolling in their programs can provide you with the necessary knowledge and certifications to embark on a successful career as a coating inspector.

Image Reference: Freepik

Disclaimer: All trademarks, logos, and brand names are the property of their respective owners. All company, product, and service names used in this website are for identification purposes only. Use of these names, trademarks, and brands does not imply endorsement.