Introduction

Coating inspection plays a pivotal role across diverse industries such as construction, manufacturing, oil and gas, aerospace, marine, and automotive. Its primary purpose is to evaluate and guarantee the quality and effectiveness of protective coatings that are applied to surfaces, equipment, or structures. These coatings are vital for shielding against corrosion, wear and tear, and the detrimental effects of the environment. By safeguarding coated objects, they ensure durability and optimal performance.

In essence, coating inspection involves a thorough examination and assessment of various aspects of a protective coating, encompassing its adhesion, thickness, uniformity, composition, and overall adherence to established standards. This evaluation is essential to ascertain that the coating effectively performs its intended functions and adheres to specified industry guidelines.

The inspection process employs a range of techniques and tools to measure and evaluate the coating’s quality. These can include visual inspections, dry film thickness gauges, adhesion tests, and specialized equipment for detecting defects such as pinholes, cracks, or voids. Properly conducted inspections help identify any defects or inadequacies in the coating, enabling timely corrections and ensuring that the intended protection and durability are achieved.

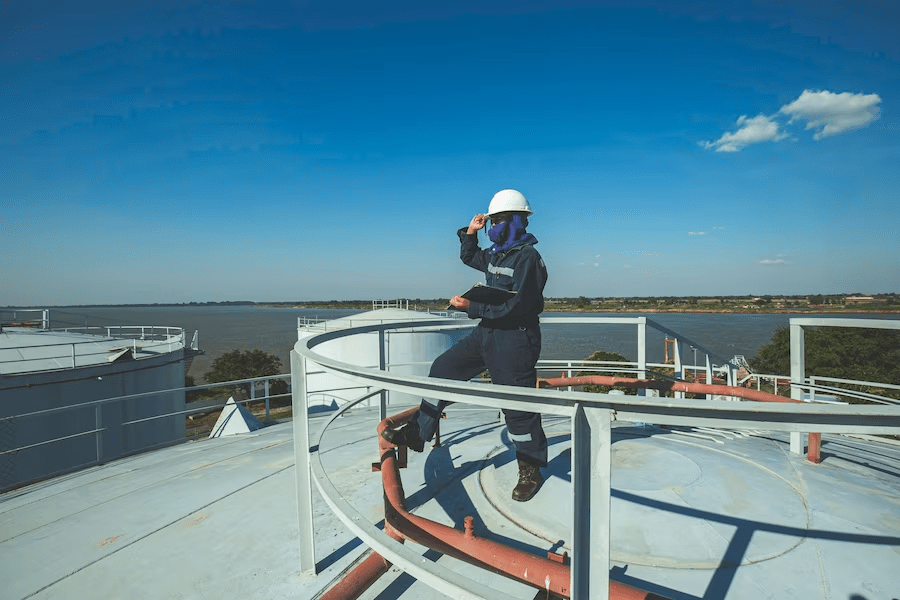

Role of Coating Inspectors

Coating inspectors play a crucial role in the process of applying coatings to various surfaces. Their primary responsibility is to ensure that coatings are applied accurately according to specified standards and requirements. Let’s delve into the specifics of their role:

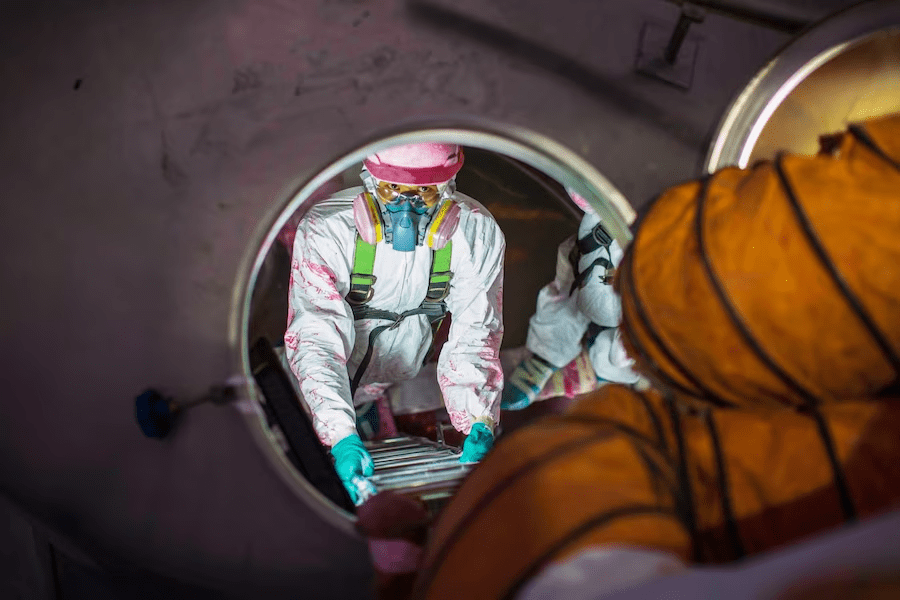

Assessing Substrate Condition

Coating inspectors begin by assessing the condition of the surface or substrate that is going to be coated. They check for any defects, contamination, or irregularities that could affect the adhesion and performance of the coating.

Verifying Surface Preparation

Before applying the coating, proper surface preparation is essential. Coating inspectors confirm that the surface has been adequately cleaned, treated, and primed to ensure the coating adheres well and provides the desired protective and aesthetic properties.

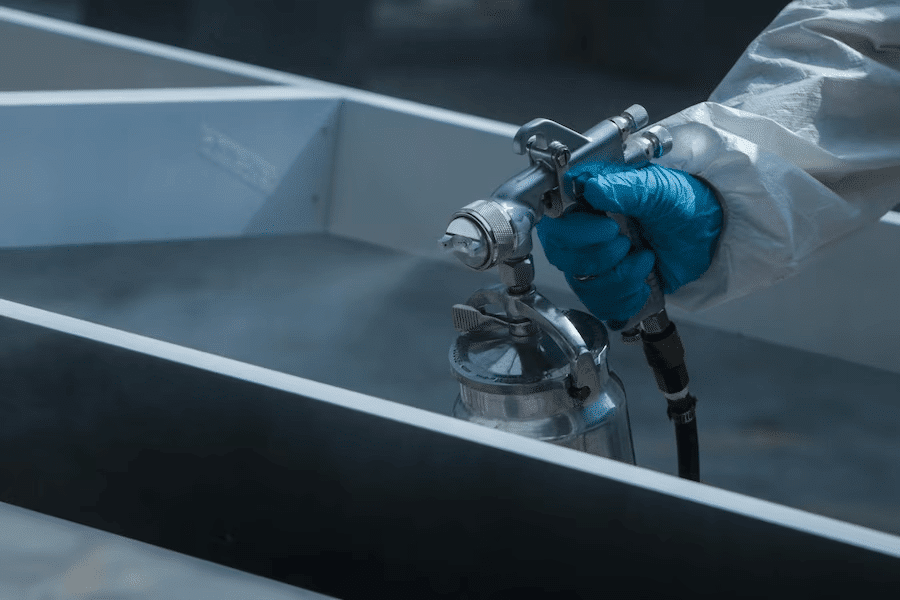

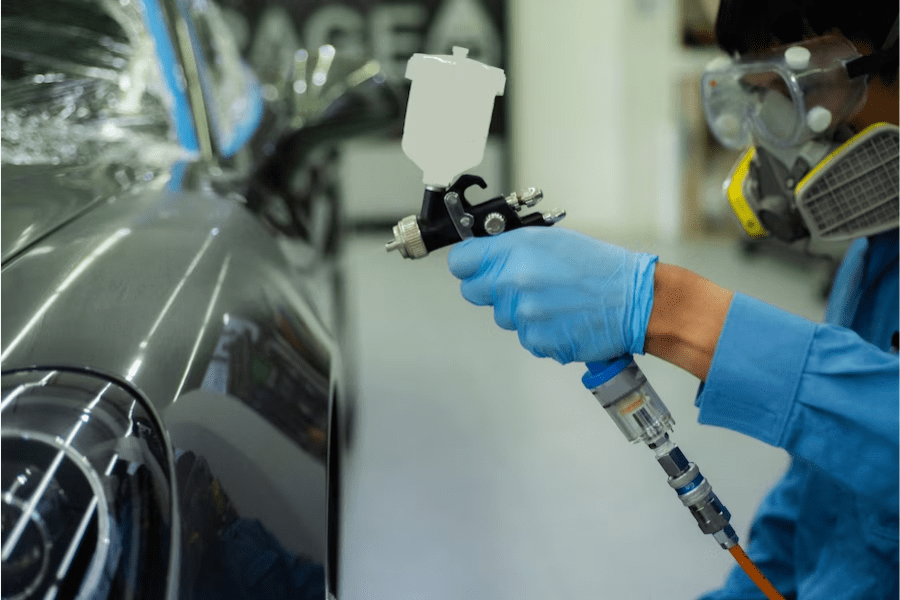

Evaluating Coating Application Techniques

Coating inspectors closely monitor the application of the coating itself. This involves assessing the methods used, such as spraying, brushing, or rolling, to ensure they align with the specified application guidelines. They check for even application, appropriate thickness, and uniformity.

Monitoring Curing Processes

After the coating is applied, it needs to cure or dry properly to achieve its intended properties. Coating inspectors oversee this process to ensure that the curing conditions (temperature, humidity, etc.) are suitable and that the coating is developing as expected.

Conducting Post-Application Inspections

Once the coating has dried or cured, inspectors conduct thorough inspections to verify that it meets the desired standards. They check for any defects, such as bubbles, cracks, or unevenness, and assess the overall quality and appearance of the coating.

Ensuring Compliance with Standards

Coating inspectors are responsible for ensuring that the entire coating process complies with industry standards, manufacturer specifications, and any relevant regulatory requirements. This is critical to guarantee the longevity, performance, and safety of the coated materials.

Contributing to Quality and Durability

Ultimately, the work of coating inspectors contributes significantly to the overall quality and durability of the coated materials. By overseeing the entire process, from surface preparation to final inspection, they help ensure that coatings perform effectively and have a long lifespan, meeting the intended functional and aesthetic objectives.

Importance of Proper Coating Inspection

Coating inspection is a critical process that involves assessing the quality and effectiveness of coatings applied to various materials. Coatings are applied to protect surfaces from corrosion, environmental factors, wear and tear, and other forms of damage. Here, we’ll delve into the importance of proper coating inspection in detail.

Ensuring Durability and Longevity

Coating inspection helps ensure that the applied coating adheres properly to the surface and forms a durable protective layer. This durability is vital for extending the life expectancy of the coated material. Properly coated materials are less likely to degrade, corrode, or wear out prematurely, ultimately saving on maintenance and replacement costs.

Preventing Corrosion and Degradation

Coatings act as a barrier against environmental elements such as moisture, chemicals, UV radiation, and abrasion that can lead to corrosion and degradation of the underlying material. Coating inspection verifies that the protective coating effectively shields the material, preventing these detrimental effects and maintaining its integrity over time.

Adherence to Standards and Regulations

Coating inspection ensures compliance with industry-specific standards, codes, and regulations related to coating thickness, adhesion, composition, and quality. Adhering to these standards is crucial for meeting safety requirements, ensuring the expected performance of the coated material, and avoiding potential legal issues.

Cost-Effectiveness

Proper coating inspection helps in catching defects or inadequacies in the coating process early on. Rectifying these issues at an early stage is more cost-effective than dealing with extensive repairs or replacements later. It minimizes wastage of resources, including materials and labor, and ensures that the coating application process is efficient.

Quality Assurance

Coating inspection is a fundamental component of quality assurance. Inspectors verify that the coating material meets specified quality standards and that the application process is carried out correctly. This guarantees that the coating will perform as intended, maintaining the structural integrity and appearance of the material.

Minimizing Risks and Liabilities

Inadequate coatings or improper application can pose safety risks, especially in industries where coated materials are critical for infrastructure or equipment. Coating inspection reduces these risks by identifying potential weaknesses in the coating, mitigating accidents, and minimizing liability for both manufacturers and end-users.

Enhancing Customer Satisfaction

Delivering a product with a high-quality, properly applied coating enhances customer satisfaction. It instills confidence in the durability and performance of the product, which is essential for customer retention and building a positive reputation in the market.

Factors Influencing Coating Inspector Salaries

The salary of a coating inspector can vary based on several key factors. Understanding these factors can help individuals plan their career paths and make informed decisions regarding education, certifications, and job opportunities.

Experience and Education

Coating inspector salaries are heavily influenced by their experience and level of education. Professionals with extensive experience and higher levels of education often command higher salaries within the field. Experience is valued as it brings practical knowledge and expertise, making inspectors more capable in their roles.

Industry and Sector

The specific industry or sector in which a coating inspector works plays a significant role in determining their salary. Industries such as oil and gas, which often involve high-risk environments and require specialized skills, tend to offer higher salaries to attract and retain talent in this field. Demand for coating inspectors in certain sectors can also drive salary levels.

Geographic Location

Geographic location is a critical factor affecting coating inspector salaries. Salaries can vary significantly based on the cost of living and market demand in a particular area. Urban areas or regions with a high cost of living generally offer higher salaries to compensate for the increased living expenses.

Certifications and Specializations

Holding relevant certifications and specializations in coating inspection can significantly impact salary levels. Certifications from reputable organizations demonstrate a high level of expertise and dedication to the profession, making individuals more valuable to employers and thus commanding higher compensation.

Company Size and Structure

The size and organizational structure of the employing company also influence salaries. Larger companies or those with complex organizational structures often have the capacity to offer higher salaries and more comprehensive benefits packages to attract and retain top talent in the coating inspection field.

Trends in Coating Inspector Salaries

In recent years, the demand for qualified coating inspectors has been steadily increasing. As industries continue to grow and innovate, the need for protective coatings to ensure longevity and performance has become paramount. This growing demand has led to a positive trend in coating inspector salaries globally.

Industry Demand

The demand for qualified coating inspectors has been on the rise due to the growth and expansion of various industries such as oil and gas, infrastructure development, and manufacturing. These sectors heavily rely on protective coatings to enhance the longevity and performance of their equipment and structures. Consequently, the demand for skilled coating inspectors has increased to ensure the proper application and maintenance of these coatings. This surge in demand has a direct impact on coating inspector salaries, driving them upwards.

Emerging Technologies

Ongoing advancements in technology have led to the development of new coating materials and more efficient application methods. Coating inspectors who possess expertise and knowledge in these emerging technologies are highly sought after by industries. Their specialized understanding of these modern coating methods is essential for ensuring effective application and maintenance. Due to the demand for these specialized skills, inspectors proficient in emerging technologies often command higher salaries.

Skill Requirements

Coating projects have become increasingly complex over time, necessitating specialized knowledge and skills in coating inspection. As a result, the skill requirements for coating inspectors have escalated. Professionals with a diverse skill set and advanced training, including in areas such as advanced coating materials, application techniques, safety protocols, and environmental compliance, are highly valued. Their ability to meet these advanced skill requirements positions them to negotiate higher salaries in line with the complexity of the projects they handle.

Tips to Maximize Coating Inspector Salary

For aspiring coating inspectors and professionals looking to increase their earning potential, here are some valuable tips to consider:

Continuous Learning and Skill Development

Staying updated with the latest developments in the field of coating inspection is vital for maximizing your salary. Coating technology and industry practices are constantly evolving, and employers seek professionals who are knowledgeable about the latest advancements. Engage in continuous learning through workshops, seminars, online courses, and industry publications. Acquiring new skills and keeping up with emerging technologies will enhance your expertise and value as a coating inspector, which in turn can lead to higher-paying opportunities.

Networking and Professional Associations

Building a strong professional network within the coating inspection industry can significantly impact your earning potential. Join industry-specific organizations and attend conferences, workshops, and networking events. Engaging with professionals in your field can provide insights into job openings, potential clients, and market trends. Networking also allows you to establish meaningful connections that may lead to referrals for high-paying projects or job opportunities.

Specializations and Certifications

Obtaining specialized certifications in key areas related to coating inspection is a strategic move to increase your salary. Certifications in corrosion control, advanced coating application techniques, or industry-specific knowledge demonstrate your expertise and dedication. Employers often value specialized certifications and may offer higher compensation for individuals with such qualifications. Additionally, these certifications can position you as a subject matter expert, making you more attractive to prospective employers.

Negotiation Skills

Developing strong negotiation skills is essential for maximizing your salary as a coating inspector. During salary negotiations, effectively communicate your qualifications, experience, and the value you bring to the organization. Highlight your achievements, certifications, and specialized skills. Research industry salary benchmarks to ensure that your compensation aligns with market standards. Practice negotiation techniques and be prepared to negotiate for a fair and competitive salary that reflects your expertise and contributions to the role.

Career Growth Opportunities for Coating Inspectors

Coating inspectors have a multitude of career advancement opportunities within the industry. With the right experience, qualifications, and skills, they can progress to higher positions that offer increased responsibilities and higher compensation.

Senior Inspection Roles

Experienced coating inspectors can move into senior roles such as Lead Coating Inspector, Senior Quality Assurance Specialist, or Corrosion Control Manager, which typically come with higher salaries and greater responsibilities.

Management Positions

With additional education and experience, coating inspectors can transition into management positions, such as Quality Control Manager, Operations Manager, or Project Manager, where they oversee entire projects and teams.

Consulting and Training

Established professionals may opt for a career in consulting or training, sharing their expertise and providing guidance to other professionals in the field. Consulting roles often come with lucrative compensation packages.

Conclusion

Proper training and education are essential for those pursuing a career as a coating inspector. The CORCON Institute of Corrosion offers valuable courses that equip professionals with the knowledge and expertise needed to excel in this vital field. By enrolling in these courses, aspiring coating inspectors can enhance their skills, increase their earning potential, and contribute significantly to the industry’s growth and sustainability.

In conclusion, a successful career as a coating inspector involves continuous learning, staying updated with industry trends, and investing in the right education. The CORCON Institute of Corrosion provides the perfect platform to achieve these goals and pave the way for a fulfilling and prosperous career in coating inspection.

Image Reference: Freepik

Disclaimer: All trademarks, logos, and brand names are the property of their respective owners. All company, product, and service names used in this website are for identification purposes only. Use of these names, trademarks, and brands does not imply endorsement.