Top Microbial Induced Corrosion-Protect Your Industry

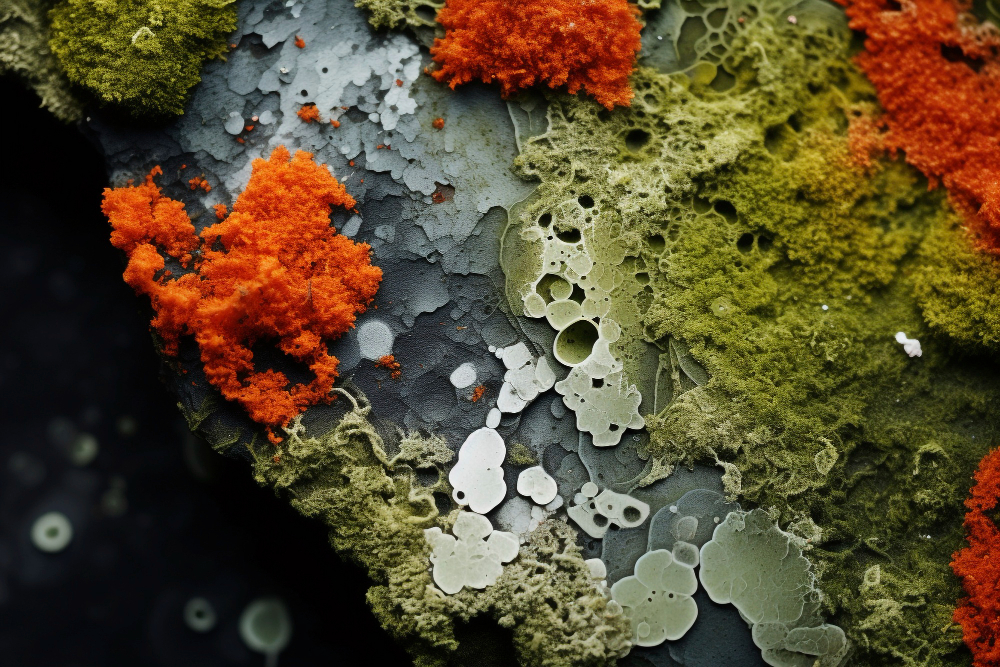

Microbial Induced Corrosion (MIC) is a significant threat to industries, particularly those involving water systems, pipelines, and storage tanks. MIC occurs when microorganisms, such as bacteria, fungi, or algae, accelerate the corrosion process by producing corrosive by-products. At CORCON Institute of Corrosion, we are committed to raising awareness and providing solutions to combat MIC. Here are some practical tips to prevent and manage MIC effectively:

1. Regular Monitoring and Inspection

- Conduct routine inspections of pipelines, tanks, and equipment to detect early signs of MIC.

- Use advanced techniques like biofilm sampling, microbial analysis, and corrosion rate monitoring to identify microbial activity.

- Implement remote monitoring systems for hard-to-reach areas to ensure comprehensive coverage.

- Document inspection results and trends to track the effectiveness of your corrosion management strategies.

2. Maintain Proper Cleaning and Hygiene

- Regularly clean and disinfect water systems, storage tanks, and pipelines to prevent microbial growth.

- Remove sludge, scale, and debris that can harbor microorganisms and create an environment conducive to MIC.

- Use mechanical cleaning methods, such as pigging for pipelines, to ensure thorough removal of deposits.

- Schedule cleaning activities during planned shutdowns to minimize operational disruptions.

3. Control Water Quality

- Monitor and control water chemistry parameters such as pH, oxygen levels, and nutrient content to limit microbial growth.

- Use biocides or antimicrobial treatments to manage microbial populations effectively.

- Test water samples regularly to ensure biocide efficacy and adjust dosages as needed.

- Avoid stagnant water conditions, as they promote microbial colonization and biofilm formation.

4. Use Corrosion-Resistant Materials

- Opt for materials that are resistant to MIC, such as stainless steel, alloys, or coatings designed to withstand microbial activity.

- Ensure proper material selection during the design phase of equipment and infrastructure.

- Consider using non-metallic materials like fiberglass or composites in highly corrosive environments.

- Regularly inspect coatings and linings for damage and repair them promptly to maintain protection.

5. Implement Cathodic Protection

- Use cathodic protection systems to reduce the risk of corrosion in pipelines and submerged structures.

- Combine cathodic protection with regular maintenance for optimal results.

- Monitor the performance of cathodic protection systems to ensure they are functioning effectively.

- Consult with corrosion experts to design and install cathodic protection systems tailored to your specific needs.

6. Educate and Train Personnel

- Provide training programs for engineers, technicians, and operators on MIC prevention and control.

- Stay updated with the latest advancements in MIC management through workshops and certifications offered by CIC.

- Encourage a culture of corrosion awareness and proactive maintenance within your organization.

- Share case studies and lessons learned from past MIC incidents to improve future practices.

7. Collaborate with Experts

- Partner with corrosion experts and organizations like CORCON Institute of Corrosion to develop tailored MIC prevention strategies.

- Attend CIC’s annual conferences, seminars, and technology meetings to learn about cutting-edge solutions and best practices.

- Engage with industry peers to exchange knowledge and experiences related to MIC challenges.

- Leverage CIC’s network of scientists, industrialists, and technocrats for guidance on complex corrosion issues.

8. Adopt Predictive Maintenance Strategies

- Use predictive maintenance tools and technologies to monitor equipment health and detect MIC-related issues before they escalate.

- Implement data-driven approaches to optimize maintenance schedules and reduce downtime.

- Integrate IoT-based sensors and real-time monitoring systems for continuous asset health assessment.

- Analyze historical data to identify patterns and predict potential MIC hotspots.

9. Conduct Risk Assessments

- Perform regular risk assessments to identify areas vulnerable to MIC.

- Develop mitigation plans based on the findings to minimize the impact of MIC on your operations.

- Prioritize high-risk areas for immediate action and allocate resources accordingly.

- Review and update risk assessments periodically to account for changes in operating conditions.

10. Stay Informed and Updated

- Leverage resources and expertise from CORCON Institute of Corrosion to enhance your corrosion management practices.

- Subscribe to industry journals and newsletters to stay informed about emerging trends and technologies.

- Participate in CIC’s educational programs to gain in-depth knowledge and practical skills in corrosion control.

Frequently Asked Questions

What is Microbial Induced Corrosion (MIC)?

Microbial Induced Corrosion (MIC) is a type of corrosion caused by microorganisms, such as bacteria, fungi, or algae. These microorganisms produce corrosive by-products like acids, sulfides, or enzymes that accelerate the degradation of metals and other materials.

What role do biofilms play in MIC?

Biofilms are colonies of microorganisms that adhere to surfaces and produce corrosive by-products. They protect microbes from biocides and create localized corrosive environments, making them a key factor in MIC.

Can MIC be completely eliminated?

While it may not be possible to completely eliminate MIC, it can be effectively managed through proper monitoring, maintenance, and mitigation strategies. Early detection and proactive measures are critical to minimizing its impact.

Are there any standards or guidelines for MIC management?

Yes, organizations like AMPP (formerly NACE International) provide standards and guidelines for MIC management, such as:

- NACE TM0212-2018: Detection, Testing, and Evaluation of MIC

- NACE SP0196-2016: Control of MIC in Oil and Gas Systems

Closing Insights

At CORCON Institute of Corrosion, we are dedicated to helping industries combat Microbial Induced Corrosion through education, awareness, and innovative solutions. By following these tips, you can significantly reduce the risk of MIC and protect your assets from costly damage.

For more information on MIC prevention, training programs, or industry collaborations, visit our website or contact us today!

Image Reference: Freepik

Disclaimer: All trademarks, logos, and brand names are the property of their respective owners. All company, product, and service names used in this website are for identification purposes only. Use of these names, trademarks, and brands does not imply endorsement.